续(二)

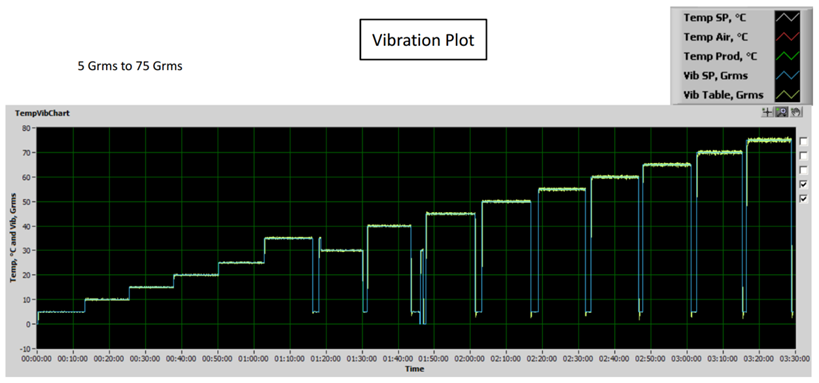

4.3 振动步进应力试验

振动步进应力是在环境温度下+20°C进行。

在测试的产品进行振动步进应力始终在设定点5GRMS的振动值,增加5GRMS的增量,10分钟的停留时间间隔。30GRMS后,振动下降到5GRMS,以确定是否发生了故障,不在更高的振动水平检测。如果在这个共振振动的检测没有故障,振动增加到下一级。

振动步进应力试验:

Setpoint (Grms) | Functional Test Result (Pass/Fail) | Notes |

0 | Pass | Sample no.2 was applied in this test. |

5 | Pass |

|

10 | Pass |

|

15 | Pass |

|

20 | Pass |

|

25 | Pass |

|

30 | Pass |

|

5 | Pass |

|

35 | Pass |

|

5 | Pass |

|

40 | Pass |

|

5 | Pass |

|

50 | Pass |

|

5 | Pass |

|

55 | Pass |

|

5 | Pass |

|

60 | Pass |

|

5 | Pass |

|

65 | Pass |

|

5 | Pass |

|

70 | Pass | The LED light panel kept flashing and the functional test items were not able to check as the value kept changing, but the LED light panel still can function and the test kept going. |

5 | Pass |

|

75 | Pass | The vibration operating limit and destruct limit was found at >75 Grms. |

5 | Pass |

|

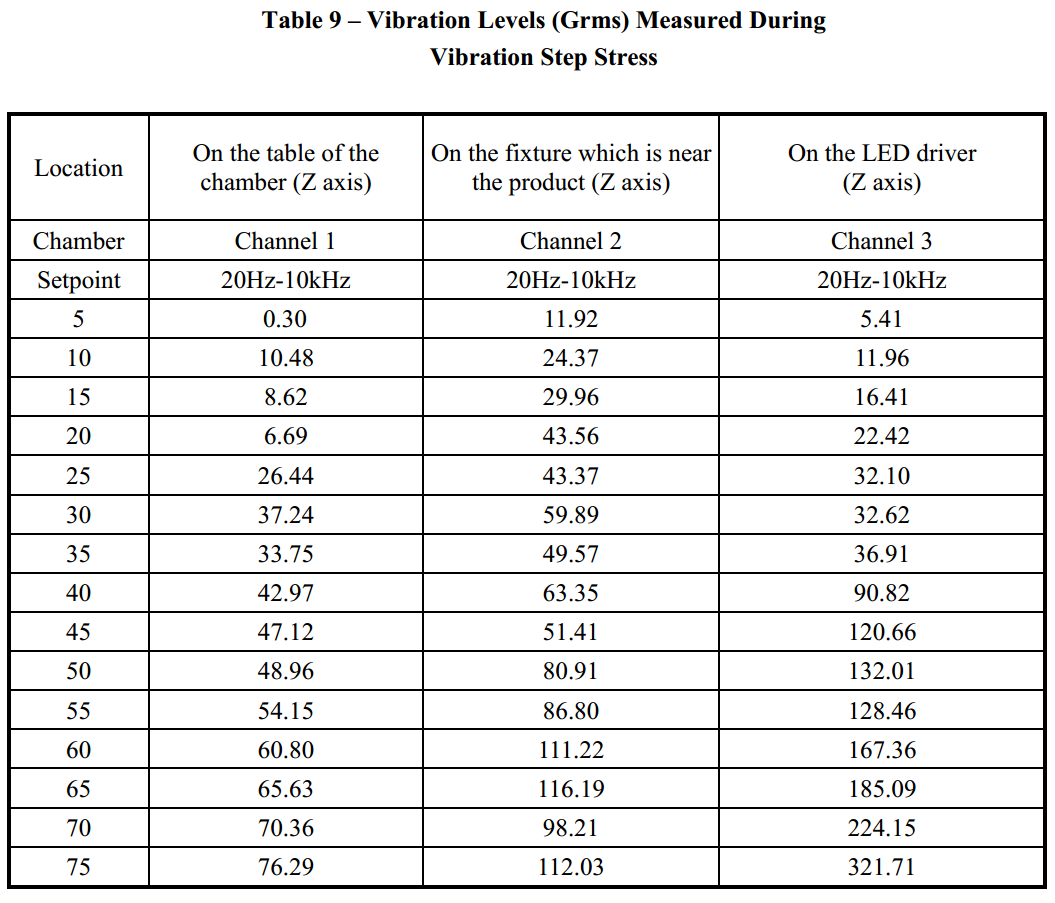

在测试LED驱动器的过程中,在振动台记录的GRMS的振动水平。产品的响应的测量带宽是从20Hz到5000 Hz。测量结果总结在表9。功率谱密度图在测量频段的能量光谱分布都包含在附录B,过低的设定点水平(5GRMS和75GRMS)。

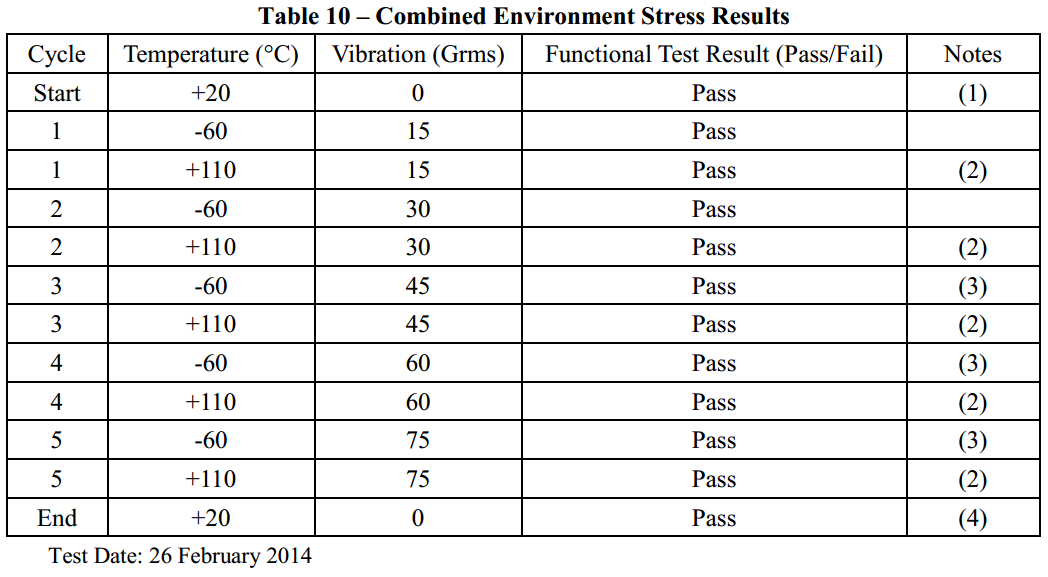

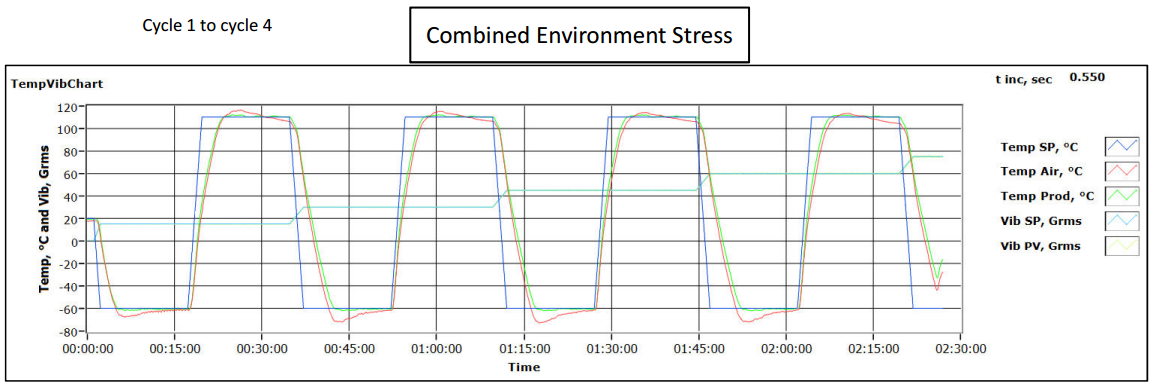

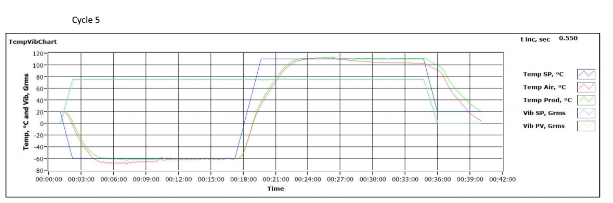

4.4 综合环境应力试验

该系统经过五次温度循环,从60℃至+ 110 °C,平均热转化率70°C/每分钟结合振动。振动开始设定点在15 GRMS,每个热循环增量为15 GRMS。在每个极端温度的停留时间为10分钟。综合环境应力试验:

结束(三),续(四)。

因篇幅所限,仅上传部分数据。

更多内容,可向易光科技公司技术支持获取。